Made with care, intention, and love.

A step by step walk through of our unique, Haandmade process.

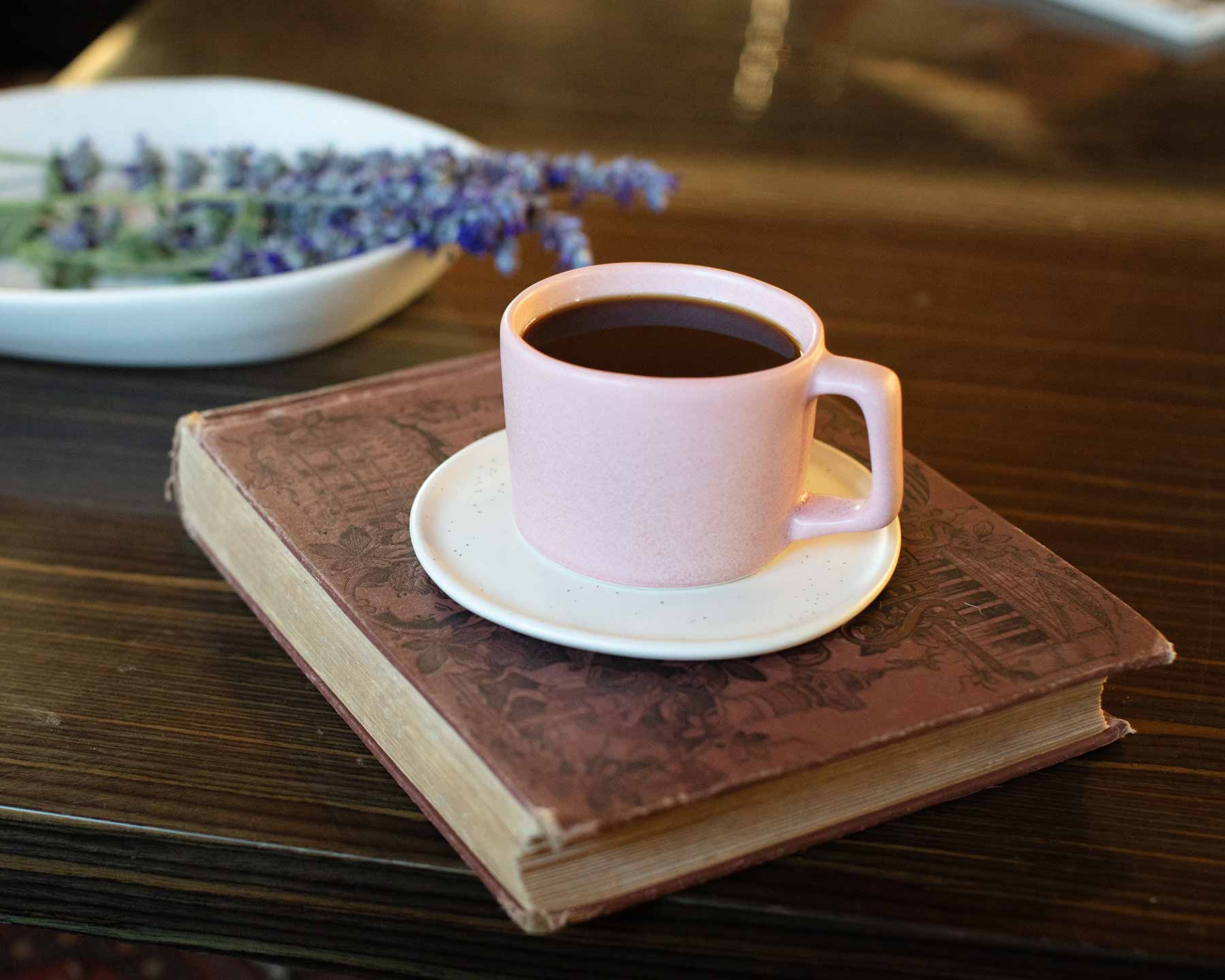

Design

Designing a mug

We do everything by hand, starting at the very beginning with Mark’s design process.

Casting

Filling molds with slip

Our ware is made using a process called slip casting. Each day, our casters fill plaster molds with a liquid porcelain slip.

Molds

Some of our many, many molds.

Our molds are made in house off of models designed and carved by Mark.

Sponging

JP cleaning and inspecting a cast piece

After the piece dries in the mold, it is removed and cleaned, smoothed with a sponge, and inspected.

Stamping

Malik stamps the bottom of a cast piece with "Haand: Made in NC, USA"

Stamping is a fun step, check the bottom of your Haand pieces and you will see the caster's chop mark and the glazer's mark too.

Bisque Firing

Much loved and abused bisque kilns

At this step, the piece is heated to 1800 degrees allowing it to become rigid, a process called bisque firing. After this firing it can be safely stored and ultimately dipped in glaze- a mixture of minerals that becomes the glassy second coating of the porcelain.

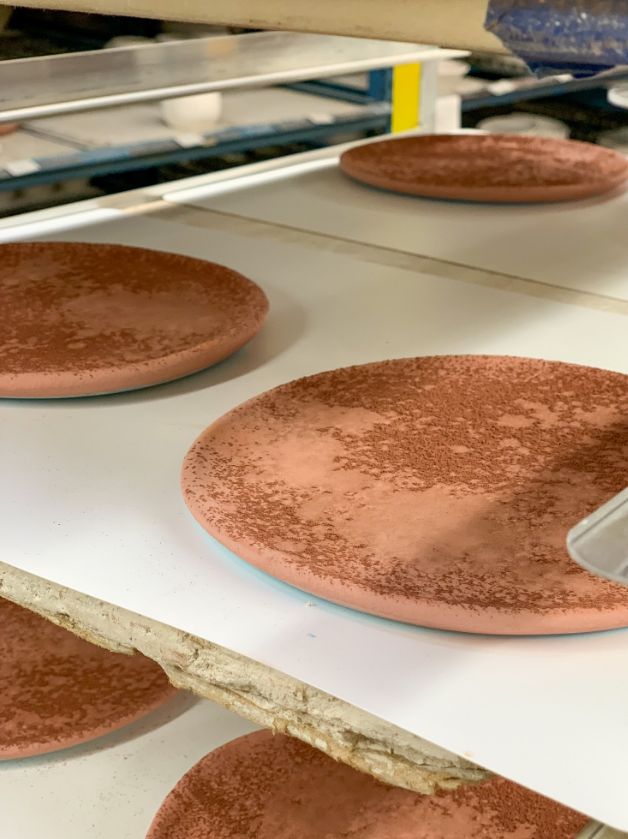

Glazing

Bob glazes a bowl

This stage is where we apply a liquid coating of minerals that fuses with the clay and becomes the outer, glassy finish and adds our distinct color and textures to each piece.

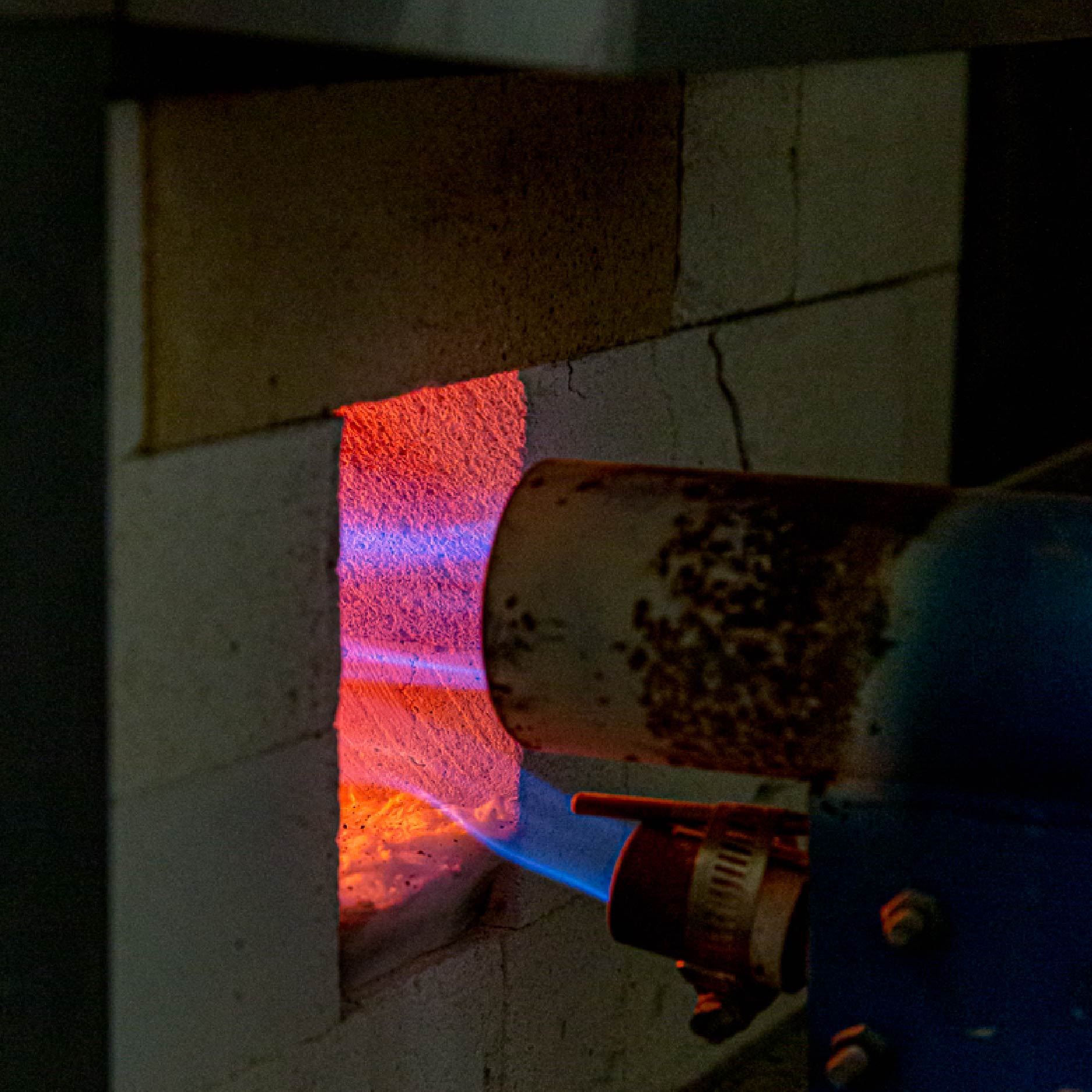

Final Firing

Our gas kiln in action

We fire our kilns to around 2300 degrees Farenheit, which allows the clay and glaze to thoroughly bond and is a key component for why our ware is so strong and durable.

Polishing

Hand polishing a mug

After the final firing, the pieces are given a final inspection and if it passes our quality control criteria, it gets polished, packed up, and shipped out.

Materials

The science and alchemy of ingredients make our pieces completely unlike anything else you have ever held in your hands.

Porcelain

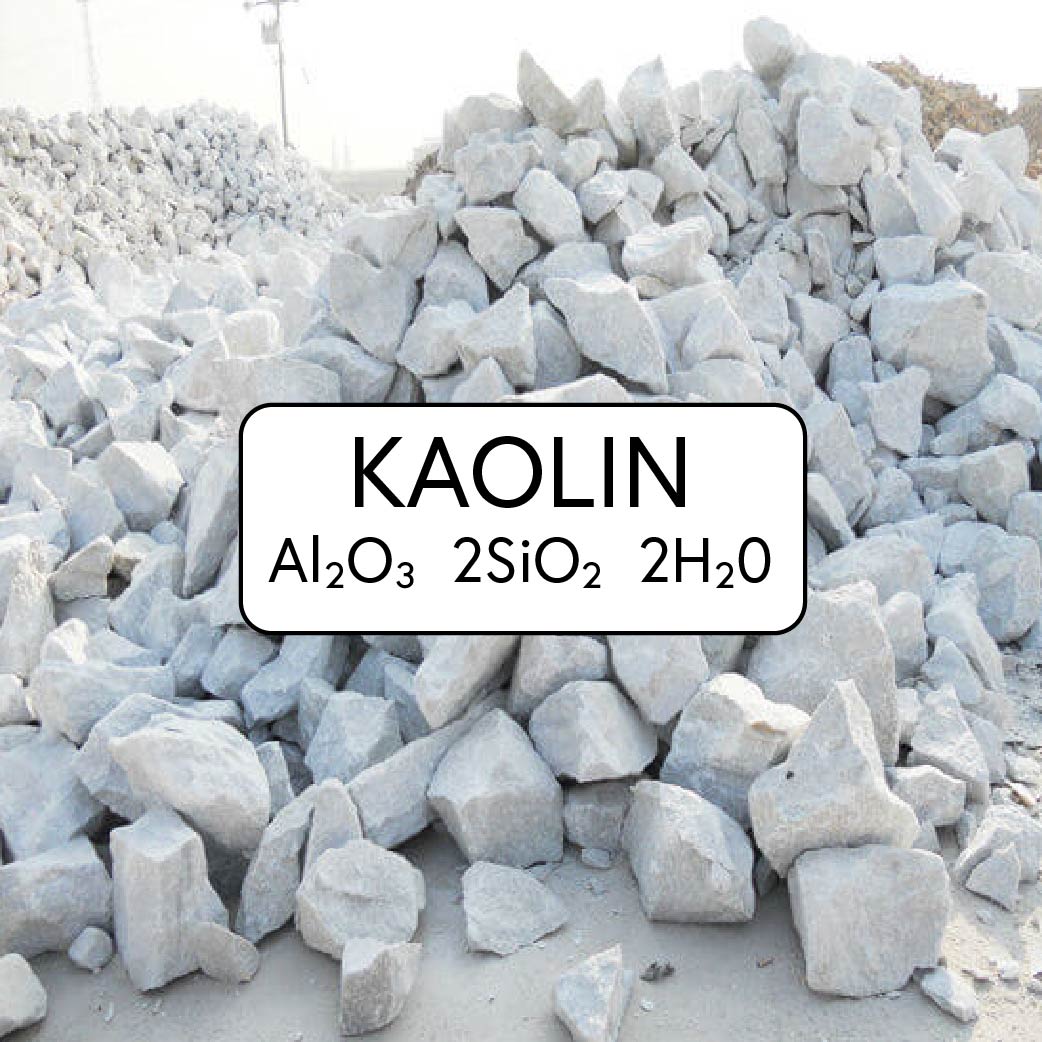

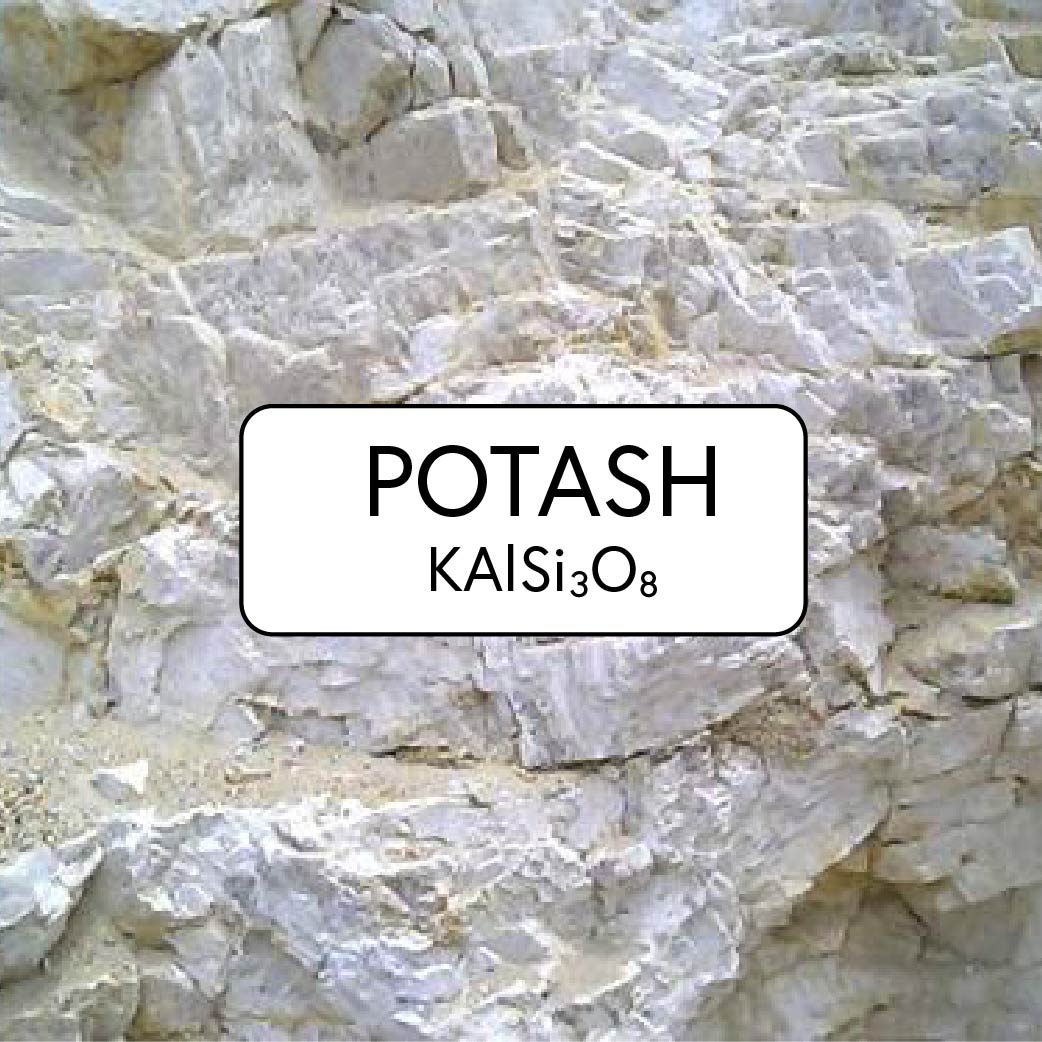

Our porcelain slip is made of Potash, Kaolin, and Flint. We intentionally fire our porcelain to the same temperatures of fine industrial porcelain, and follow strict guidelines for selecting colorants and glazes with the intention of creating a safe, ethically sourced product that you, the end user, can proudly and joyfully use. Our materials have been hand-selected carefully over time through years of testing and refinement.

Our Slip Ingredients

The glass former in our clay body, with the help of kaolin and feldspar, it melts and forms the distinct glassy, vitrified surface of our porcelain ware. Flint is a sedimentary rock, and it's the same material used extensively by the early humans to make tools and start fires. The deposit that our flint is mined from in Tennessee was part of an extensive pre-Columbian trade network that spanned the Southeastern and East Coast of the US due to it’s superb quality when used in arrowheads and spear points.

Kaolin is the clay component of our slip. It is referred to as a “primary clay”, meaning it has not traveled from the site of its origin. This clay is formed by the chemical weathering of feldspathic rocks from warm acidic rain, a reminder that when the deposit was formed in Cornwall, England, the area around it was a tropical rainforest.

Feldspathic rocks are some of the most common in the world, making up 41% of the earth’s crust. In our clay body they act as the structure that helps bring together the flint and kaolin, helping both melt together and form our hard white porcelain. Without these humble rocks, pottery could not exist, so much so that it is referred to as Potter’s Stone.

Glazes

We formulate all glazes in our studio to ensure control of the final color and finish. We carefully select and test all of our formulas and ingredients to ensure just the right balance is struck between the natural and the refined, and spend years honing and tweaking until it is all just right. Our porcelain and glazes combine to have a completely unique feeling in your hand. Each glaze formula can have individual quirks, and glazers will adjust the amount of time a piece is dunked and how they turn their wrists to allow the glaze to drain off consistently.